Recon-o-Sense Moisture Sensor

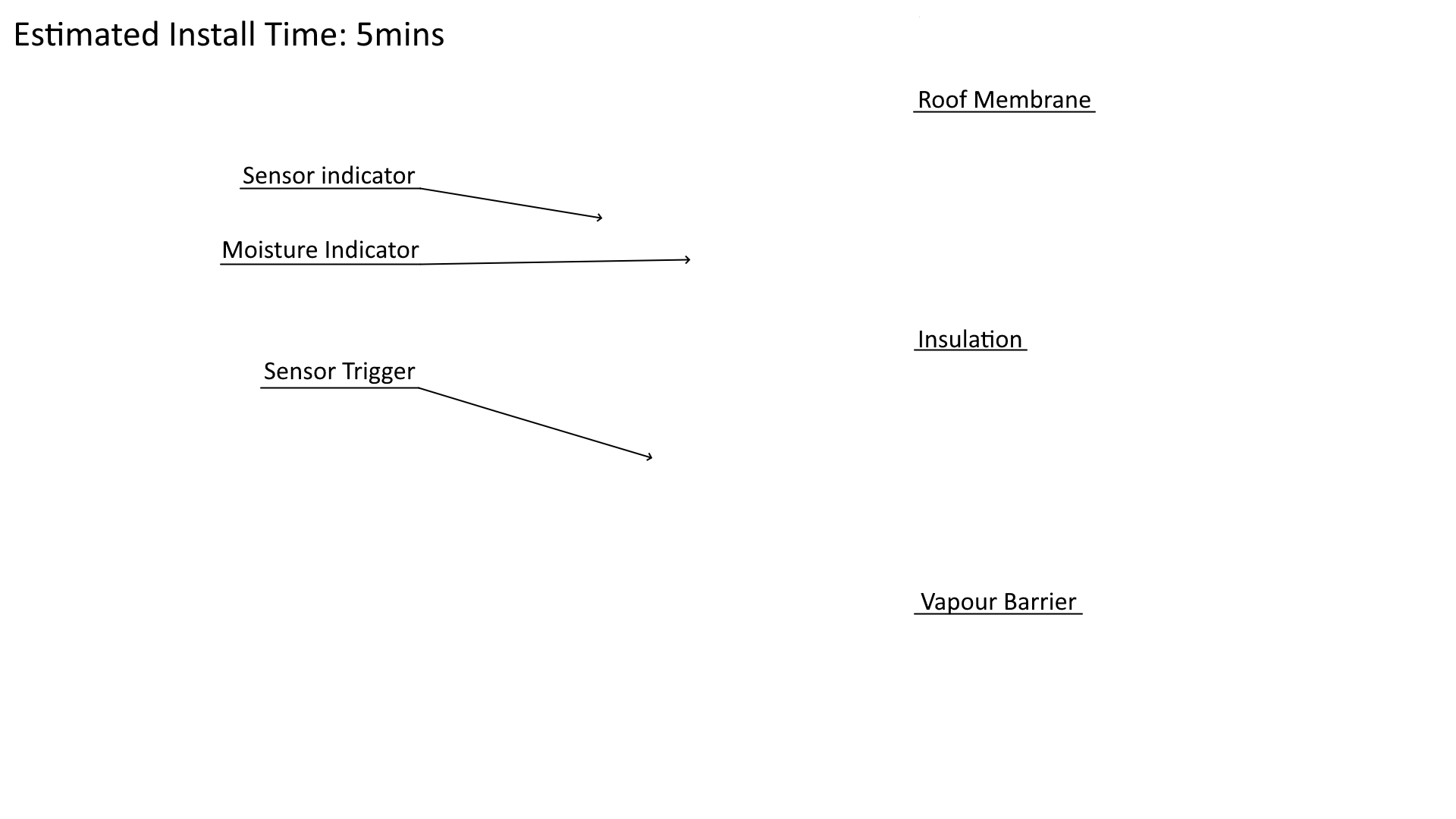

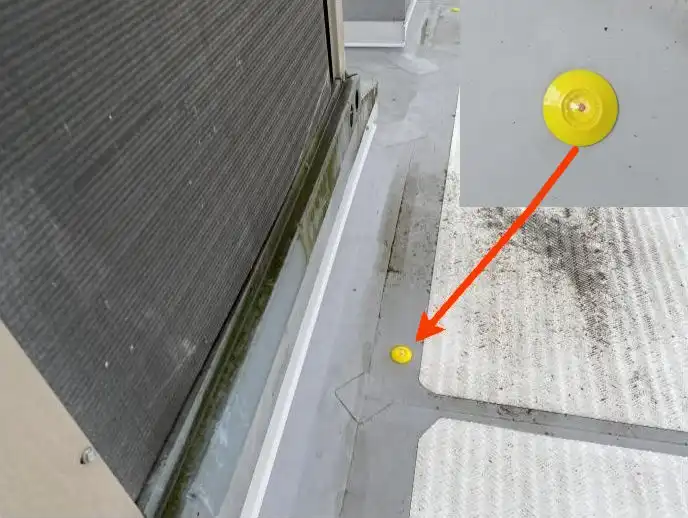

The Recon-o-Sense Moisture Sensor is a two-part system installed below and above the roof membrane without any holes or punctures in the roof membrane. It will sense if there is hidden moisture in the roof system and alert the maintenance personnel that there is a problem.

Application:

● Near roof projections (Roof curbs, HVAC, Vents, Drains, Walls, and other roof projections) where 80% of leaks occurs.

● Under cooling towers, hot-air exhaust, or other dangerous equipment, allowing inspections from a distance.

● Optional: Near the edge of rooftops, the Recon-o-Sense moisture sensor can be viewed from 8 feet away making it safe to use while inspecting roof projections

● Optional: Installed in the field area to get extended coverage

Recon-o-Sense moisture sensors types available:

● Recon-o-Sense Long Reach Sensor for single ply (1" to 7")

● Recon-o-Sense Short Reach Sensor for single ply (½" to 1").

● Recon-o-Sense Long Reach Sensor for 2-ply SBS (1" to 7")

● Recon-o-Sense Short Reach Sensor for 2-ply SBS (½" to 1").

Accessories:

● Recon-o-Sense Accessory Install Kit

Quick to install (5 mins to install) and can be installed on EPDM, TPO, PVC and 2-ply SBS roofs.

FEATURES AND BENEFITS

● Performing 24/7 without monitoring fees.

● Improved reporting of leaks into roof systems.

● Keeps contractors, roof crews and inspectors alert to roof leaks.

● Getting repairs done under warranty.

● Saving on heating and cooling costs by helping to keep roofs dry.

● Helps extend the life expectancy of roofs.

● Improves safety by minimizing the risk of falls during roof inspections.

Click here for info on product specifications

Helps Find Hidden Moisture

Using the Recon-o-Sense moisture sensor installed near roof top equipment, allows roof inspectors and building maintenance personnel to detect wet roof insulation using only visual observation. No infrared cameras required.

Hidden moisture leaks in low slope roofs are common and can be costly as it spreads out over time. With today's roof vapour barriers, roof leaks can go undetected for years damaging the roofs insulation that could have been stopped with earlier reinforcement repairs.

Experienced roof inspectors walk roofs and look for defects above the roof such as blisters, open seams, or failed caulking... However, with only visual observation, they cannot see beneath the membrane to determine if the insulation is wet.

Roof Industry Statistics

● 40 percent of all building-related problems are due to water intrusion that usually caused by roof related leaks.

● Roof systems only make up about 2 percent of the buildings construction costs, but water intrusion accounts for more than 70 percent of construction litigation. Roof failures are the usual cause.

● The most widespread problem that leads to roof failures is deficient design specifications or improper installation, example at design detail transitions, joints, terminations, and penetrations, which are not professionally installed by the roofing contractor.

● Warranties are not a substitute for a professionally designed, installed, and maintained roof.

● Warranties rarely cover the replacement of wet insulation damaged by water intrusion that is costly to replace.

● Roof equipment technicians and maintenance personnel can cause damage to the roof membrane, which can either go unnoticed or reported.